Editor: What is Digital Transformation

It is hard to define "Digital Transformation" since understandings of the term vary from different perspectives: in the eyes of engineers, it concerns "big data, artificial intelligence, Internet of things, and Cloud Computing"; in the discourse of macroeconomic policy-makers, it includes "industrial digitalization, digital industrialization, data value, and digital governance"; while “digital transformation models” such as Microsoft's "digital feedback loop" and IBM's "digital remodeling methodology" will be introduced when consulting companies are involved. If we get into the realm of business practices, “digital transformation” covers numerous business models and innovations.

Hence, we need to elaborate our definition of “Digital Transformation” before we can discuss on the issue. Based on the past few years of researches and practices, we tentatively reached two conclusions:

First, as for the definition of digital transformation, I would like to adopt the concept proposed by Professor Mao Jiye, Director of the Business School of Renmin University of China: Digital Transformation is Reconstructing Business and Organization with Digital Technology.

Second, from practice, we summarize there are two paths for digital transformation, named as “demand drives supply” and “supply creates demand”.

How to Reconstruct Business and Organization along “Demand drives supply”

First, let's look at how digital technology can restructure business and organization through "demand drives supply".

The process of "demand drives supply" involves two stages of reconstruction: firstly, to reconstruct the relationship between the company and the end users, or "building a dynamic customer network". Secondly, the new and “unmet” demand resulted from the “dynamic customer network” will drive the supply chain to be reconstructed to meet the new demand.

What is dynamic customer network? In the past, we regard users as a large-scale market, and the communication between seller and customers is one-way. Therefore, traditional marketing focuses on advertising, spreading information in a wide way with the purpose of influencing customers' purchase activity. But in the digital age, we need more two-way communication. Sellers must reach and link users in various ways to obtain real and timely data from the end users. Only in this way, sellers can redefine products or services according to user demand, providing value and obtaining user loyalty. This is the evolution from "scale economy" to "value economy" in the digital era.

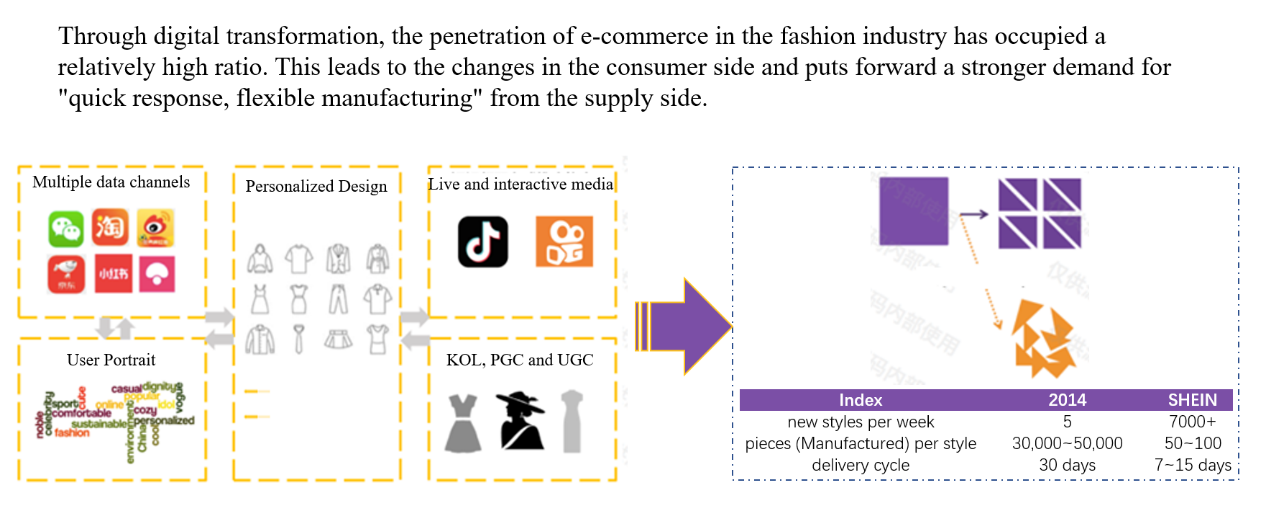

The second stage of reconstruction involves supply chain. Digital technology has changed the consumption habits and behavior of users, while the change of demand side has given birth to new modes of supply side such as small-scale customization, network collaboration, service-oriented manufacturing, etc. Let's take the fashion industry as an example to explain the transformation process.

In the past few years, we have studied the textile and clothing industry. We found that there is a big difference between the processes of factories of E-commerce and the traditional garment manufacturing enterprises: the new product cycle is shorter, the minimum order quantity of each model is smaller, and the cost is lower. This supply chain mode is named as "small order, quick response" in the industry.

SHEIN, which we introduced in the "Trade Digitization" column, is a good illustration of this digital transformation model.

How to Reconstruct Business and Organization along “Supply creates demand”

If we say that the starting point of digital reconstruction along "demand drives supply" is digital marketing, then, the starting point of digital reconstruction along the "supply creates demand" is product Digitization. The digitization of products on the supply side will promote the digital transformation of downstream distributors and service providers, and then drive the overall transformation and upgrading of the industrial chain.

Here, we take the digital transformation of the electronic industry as an example.

Strictly speaking, the upgrading of electronic products may be named as "smart upgrading" other than "digital upgrading". The smart upgrading of electronic products has developed rapidly in recent years in China and attracted more and more attention, which owns its credit to the popularity of cloud computing, artificial intelligence, and the commercialization of low-power, wireless technology and edge computing technology. The gradual growth and maturity of AIoT (Smart Internet of things) platform such as Huawei, Xiaomi, TUYA and AWS have led to the overall upgrading of industrial chain ecology.

The AIoT platforms provide one-stop solution to empower the smart upgrading of traditional manufacturing enterprises. By the hardware modules and software development framework provided by the platform, traditional enterprises can easily connect their products to the Internet of things. Once connected, the products can be integrated into the ecology of various smart service scenarios, together with thousands of other smart devices of the ecology. The platforms’ evolving artificial intelligence, big data and other advanced technical services can also ensure the SMEs’ further smart upgrading, for example, from traditional access control to employee behavior analysis, or from traditional meter reading to energy optimization.

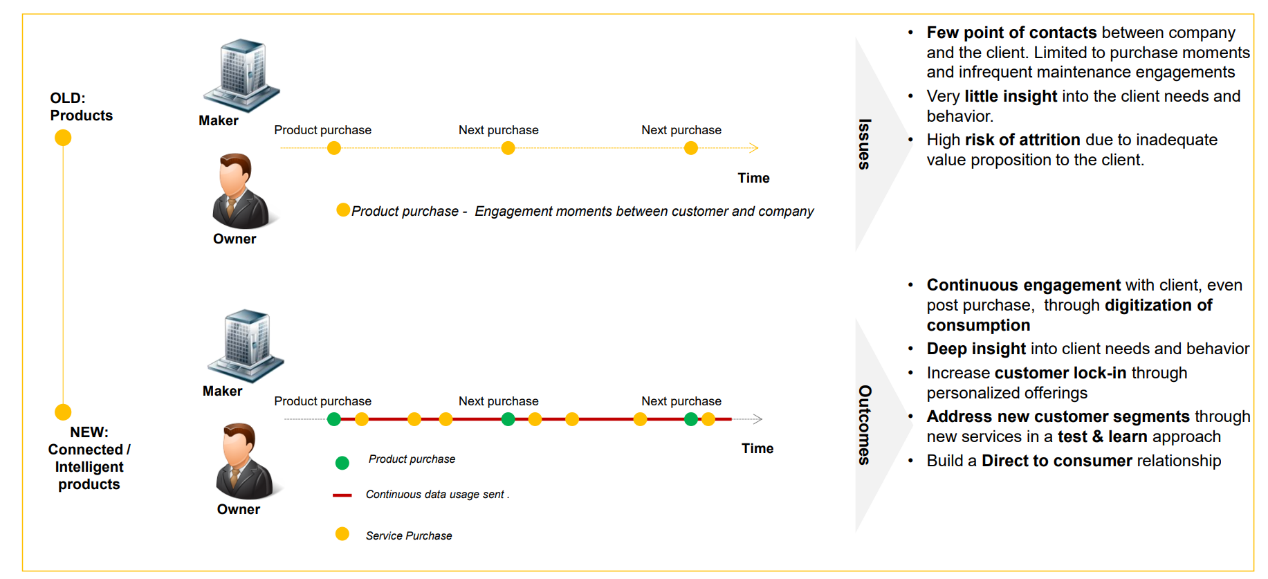

Thus, basing on the IoT platform, the manufacturers, distributors, brands, service providers can provide new and smart products and services to their customers and seize the engine of new business. Additionally, by providing the “product-service hybrid” to their customers, the providers can continuously engage with client and have deep insight into clients need and hence increase customer lock-in through personalized offerings.

Combination of products and services to improve user experience

Resource: Prith Banerjee, Driving Unconventional Growth through The Industrial Internet